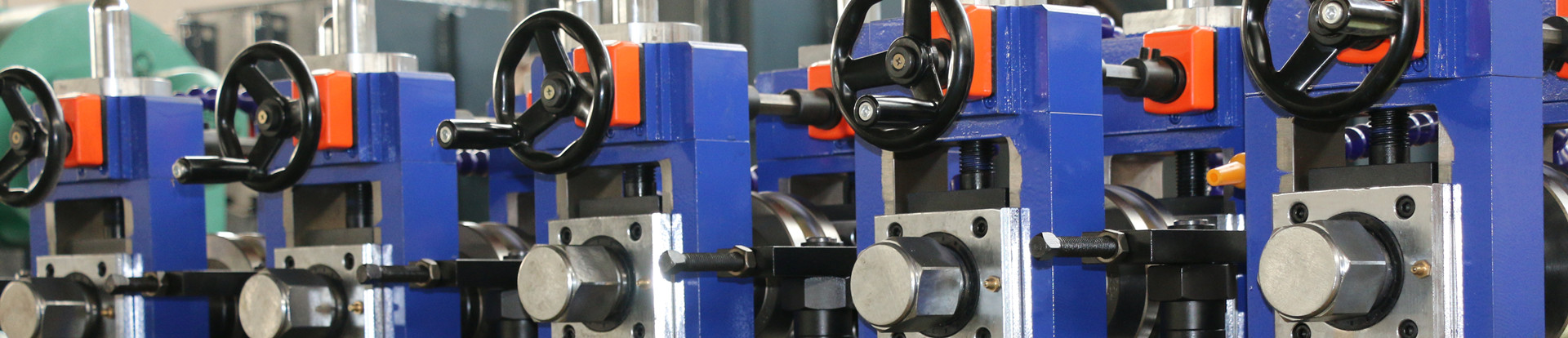

18 Years Factory Steel Tube Straightening Machine - Friction Saw – TUBO Detail:

Product Description

It is the mechanical equipment which used in continuously production, Auto Fixed ruler cutting steel pipes , which is one of the element support device for weld pipe production line .

Low inertia DC motor through mechanical transmission device,measuring, calculate and driving saw car at the same speed with the high speed running pipe , then cut off the pipe with specified length .

Advantage

1.Economic

2.2.reduce investment .

Specification

|

Flying cut off |

|

|

Tube Diameter |

6~168mm |

|

Wall Thickness |

0.3~6mm |

|

Working Speed |

60~120m/min |

Product detail pictures:

Related Product Guide:

abide by the contract", conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for 18 Years Factory Steel Tube Straightening Machine - Friction Saw – TUBO , The product will supply to all over the world, such as: Philippines , Serbia , Swedish , We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!