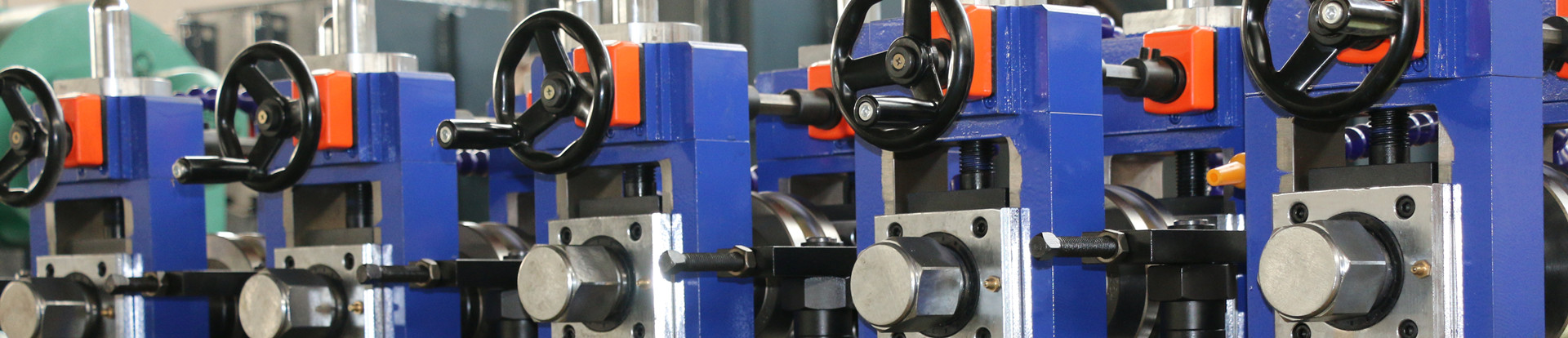

2020 High quality Stainless Steel Roll Forming Machine - Rollers – TUBO Detail:

Product Description

Used for roll forming of steel tubes, Specific sets of rollers can be used to bend strip steel into steel tubes of the required Diameter.

Tube Roller Process

In order to obtain qualified modes, we built a quality control system and applied this process:Raw material – sawing material – rough processing – Drilling –fine finishing – roller polishing – Typing Code – semi-finished product inspection – heat treatment – grinding hole – horizontal die cutting – quality inspection – oil cleaning – packaging

Specfication

| Material | GCr15, Cr12,Cr12MoV, Can be customized |

| Hardness of roller | HRC58-62 |

| Deepness of quench hardening | ≥ 10mm |

| Roughness of surface | Ra≤0.8um |

Product detail pictures:

Related Product Guide:

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for 2020 High quality Stainless Steel Roll Forming Machine - Rollers – TUBO , The product will supply to all over the world, such as: Namibia , Sydney , Florida , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.