2020 New Style 20 Stainless Steel Automatic Pipe Welding Machine - Cold Cutting Saw – TUBO Detail:

Product Description

Our Cold cutting saw can reach high precision(±1.0mm)and the pipe ends is smooth with no burr. Both nice in carbon&stainless steel products.

Product Details

1.Automated cutting inline.

2.LCD touch screen.

3.High speed and high precision cutting .

4.Excellent cutting surface, no burrs&save costs.

Model List

| Model NO. | Steel pipe diameter (mm) | Steel pipe thickness (mm) | Max speed (M/min) |

| Φ25 | Φ6-30 | 0.3-2.0 | 120 |

| Φ32 | Φ8-38 | 0.3-2.0 | 120 |

| Φ50 | Φ20-63.5 | 0.6-2.5 | 100 |

| Φ76 | Φ25-76 | 0.8-3.0 | 100 |

| Φ89 | Φ25-105 | 0.8-4.0 | 80 |

| Φ114 | Φ50-130 | 1.2-5.0 | 60 |

| Φ168 | Φ80-168 | 2.0-6.0 | 60 |

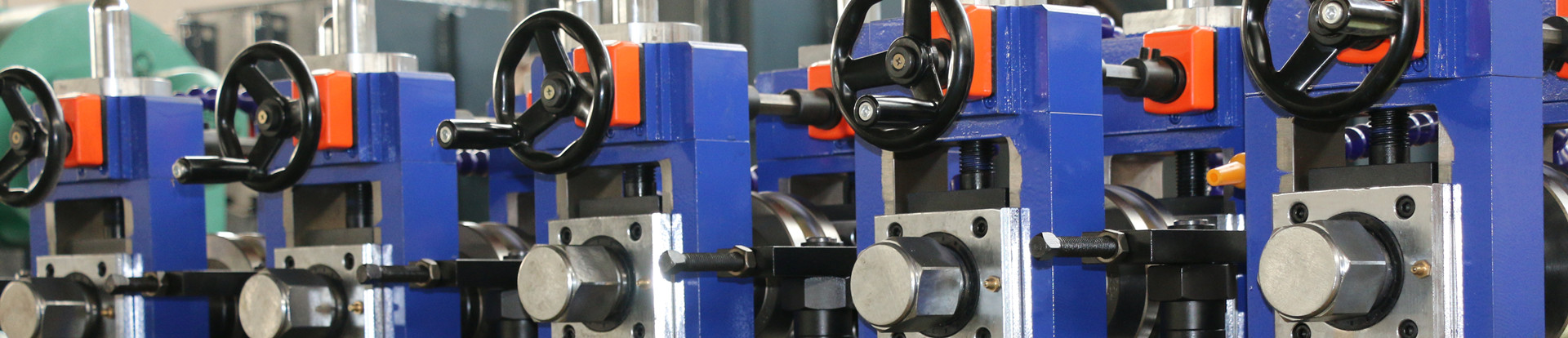

Main Components of the Equipment

1. main Machine

2. hydraulic system

3. main host of the cut-off

4. Operation desk (electrical control cabinet: to be installed in the electrical control room)

5.speed measurement roller

Specification

|

Technical Parameters |

||

|

Material |

Carbon Steel |

|

|

Tensile strength |

<400N/mm2 |

|

|

Pipe Size |

Round Pipe |

48~127mm |

|

Square Pipe |

40*40~100*100mm |

|

|

Rectangle Pipe |

50*30~140*60mm |

|

|

Thickness |

1.0~5.0mm |

|

|

Cutting Length |

<32 Continuous Adjusting |

|

|

Speed |

Max.80m/min |

|

|

Servo/AC Motor |

Driving Motor |

YASKAWA/SIEMENS |

|

Feeding Motor |

YASKAWA/SIEMENS |

|

|

Cutting Motor |

YASKAWA/SIEMENS |

|

|

Saw Blades |

HSS/TCT |

|

Product detail pictures:

Related Product Guide:

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for 2020 New Style 20 Stainless Steel Automatic Pipe Welding Machine - Cold Cutting Saw – TUBO , The product will supply to all over the world, such as: Chile , America , Kyrgyzstan , We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.