China wholesale Cut To Length Line - Cut-To-Length Line – TUBO Detail:

Product Description

We can provide customzied cut to length proposal for all dimensions, From hot-rolled strip to thinnest cold-rolled, From Aluminum to stainless steel . In strip widths from 120mm~2,500mm and strip thickness from 0.5mm~20.0mm

Application: The metal coil decoiling, leveling and cut to length line is applied on cold-rolled steel, Hot-rolled steel, carbon steel, stainless steel, galvanized steel, color steel plates and other metal materials.

Process Flow

Coil preparation → Feeding → Uncoiling → Peeler → Reverse bending roll → Pinch feeding → Pre-leveling → Loop bridge → Aligning Device → Precision Leveling → fixed length measurement → tail board pinching → Flying Shear → Conveying → discharge frame → Lifting table→discharge car

Advantage

1.High Precision.

Extremely perfect flatness of sheets by using”four-high” and “six-high”levelers.

2..Elimination of edge waves and center buckles by approaching rows of back-up rolls in the leveling machine .

High production capacity and flow rates by rigorous mimimizaiton of tooling times and high production speeds.

4.Exact cutting accuracy and angularity of sheets.

5.Cutting with little burr by the edge-trimming shear and the cut-to-length shear.

6.High stacking accuracy by using individual stacking systems.

7.Gentle treatment of high-sensitive surfaces such as surface for the automotive industry by special transport and stacking methods .

Specfication

| Model | Thickness | Width | Length | Leveling speed |

| CTL-2×1000 | 0.2~2.0mm | 400~1000mm | adjustable | Max 100m/min |

| CTL-3×1250 | 0.3~3.0mm | 500~1250mm | adjustable | Max 100m/min |

| CTL-4×1500 | 0.6~4.0mm | 500~1500mm | adjustable | Max 80m/min |

| CTL-5×1600 | 1.0~5.0mm | 500~1600mm | adjustable | Max 80m/min |

| CTL-6×1600 | 1.0~6.0mm | 600~1600mm | adjustable | Max 40m/min |

| CTL-8×1800 | 2.0~8.0mm | 1000~1800mm | adjustable | Max 30m/min |

| CTL-10×2000 | 3.0~10.0mm | 1000~2000mm | adjustable | Max 30m/min |

| CTL-12×1600 | 3.0~12.0mm | 600~1600mm | adjustable | Max 20m/min |

| CTL-16×1800 | 4.0~16.0mm | 1000~1800mm | adjustable | Max 20m/min |

| CTL-20×2000 | 5.0~20.0mm | 1000~2000mm | adjustable | Max 20m/min |

| CTL-25×2500 | 8.0~25 | 1000~2500mm | adjustable | Max 20m/min |

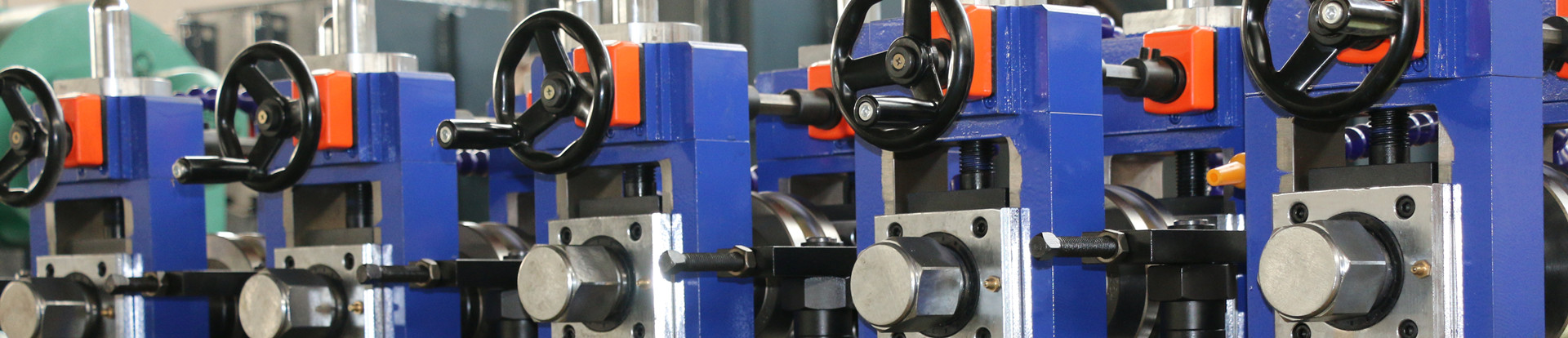

Product detail pictures:

Related Product Guide:

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for China wholesale Cut To Length Line - Cut-To-Length Line – TUBO , The product will supply to all over the world, such as: Atlanta , Philippines , Borussia Dortmund , With the support of our highly experienced professionals, we manufacture and supply best quality products. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the need of customers to meet the requirement of customers.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.