Product Description

Our Cold cutting saw can reach high precision(±1.0mm)and the pipe ends is smooth with no burr. Both nice in carbon&stainless steel products.

Product Details

1.Automated cutting inline.

2.LCD touch screen.

3.High speed and high precision cutting .

4.Excellent cutting surface, no burrs&save costs.

Model List

| Model NO. | Steel pipe diameter (mm) | Steel pipe thickness (mm) | Max speed (M/min) |

| Φ25 | Φ6-30 | 0.3-2.0 | 120 |

| Φ32 | Φ8-38 | 0.3-2.0 | 120 |

| Φ50 | Φ20-63.5 | 0.6-2.5 | 100 |

| Φ76 | Φ25-76 | 0.8-3.0 | 100 |

| Φ89 | Φ25-105 | 0.8-4.0 | 80 |

| Φ114 | Φ50-130 | 1.2-5.0 | 60 |

| Φ168 | Φ80-168 | 2.0-6.0 | 60 |

Main Components of the Equipment

1. main Machine

2. hydraulic system

3. main host of the cut-off

4. Operation desk (electrical control cabinet: to be installed in the electrical control room)

5.speed measurement roller

Specification

|

Technical Parameters |

||

|

Material |

Carbon Steel |

|

|

Tensile strength |

<400N/mm2 |

|

|

Pipe Size |

Round Pipe |

48~127mm |

|

Square Pipe |

40*40~100*100mm |

|

|

Rectangle Pipe |

50*30~140*60mm |

|

|

Thickness |

1.0~5.0mm |

|

|

Cutting Length |

<32 Continuous Adjusting |

|

|

Speed |

Max.80m/min |

|

|

Servo/AC Motor |

Driving Motor |

YASKAWA/SIEMENS |

|

Feeding Motor |

YASKAWA/SIEMENS |

|

|

Cutting Motor |

YASKAWA/SIEMENS |

|

|

Saw Blades |

HSS/TCT |

|

Company Introduction

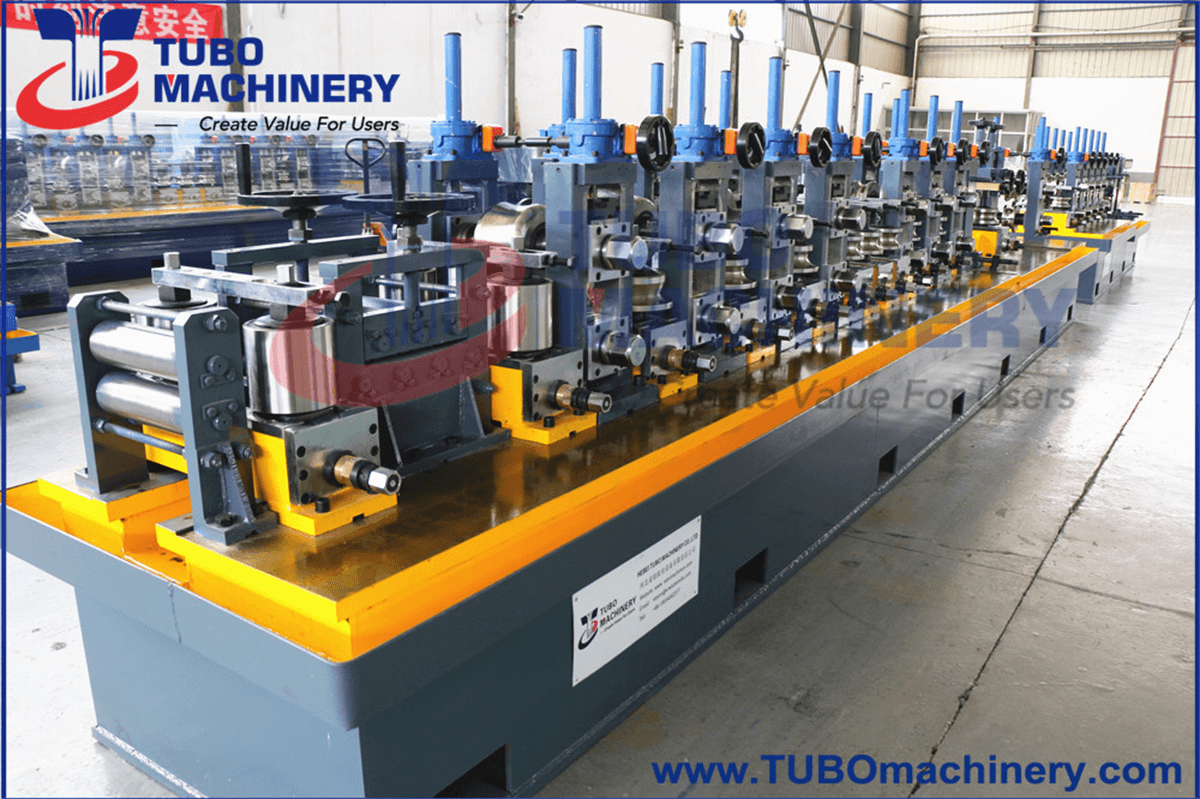

Hebei Tubo Machinery Co.,LTD is a high-tech enterprise registered in Shijiazhuang City. Hebei Province. It specialized in Developing and Manufacturing for the complete set of equipments and related technical service of High Frequency Welded Pipe Production Line and Large-size Square Tube Cold Forming Line .

Hebei Tubo Machinery Co.,LTD With more than 130 sets all types of CNC machining equipment, Hebei Tubo Machinery Co.,Ltd., manufactures and exported to over 15 countries of welded tube/pipe mill, cold roll forming machine and slitting line, as well as auxiliary equipment for more than 15 years.

TUBO Machinery, as a partner of users, provides not only high precision machine products, but also technical support everywhere & anytime.

Our Workshop

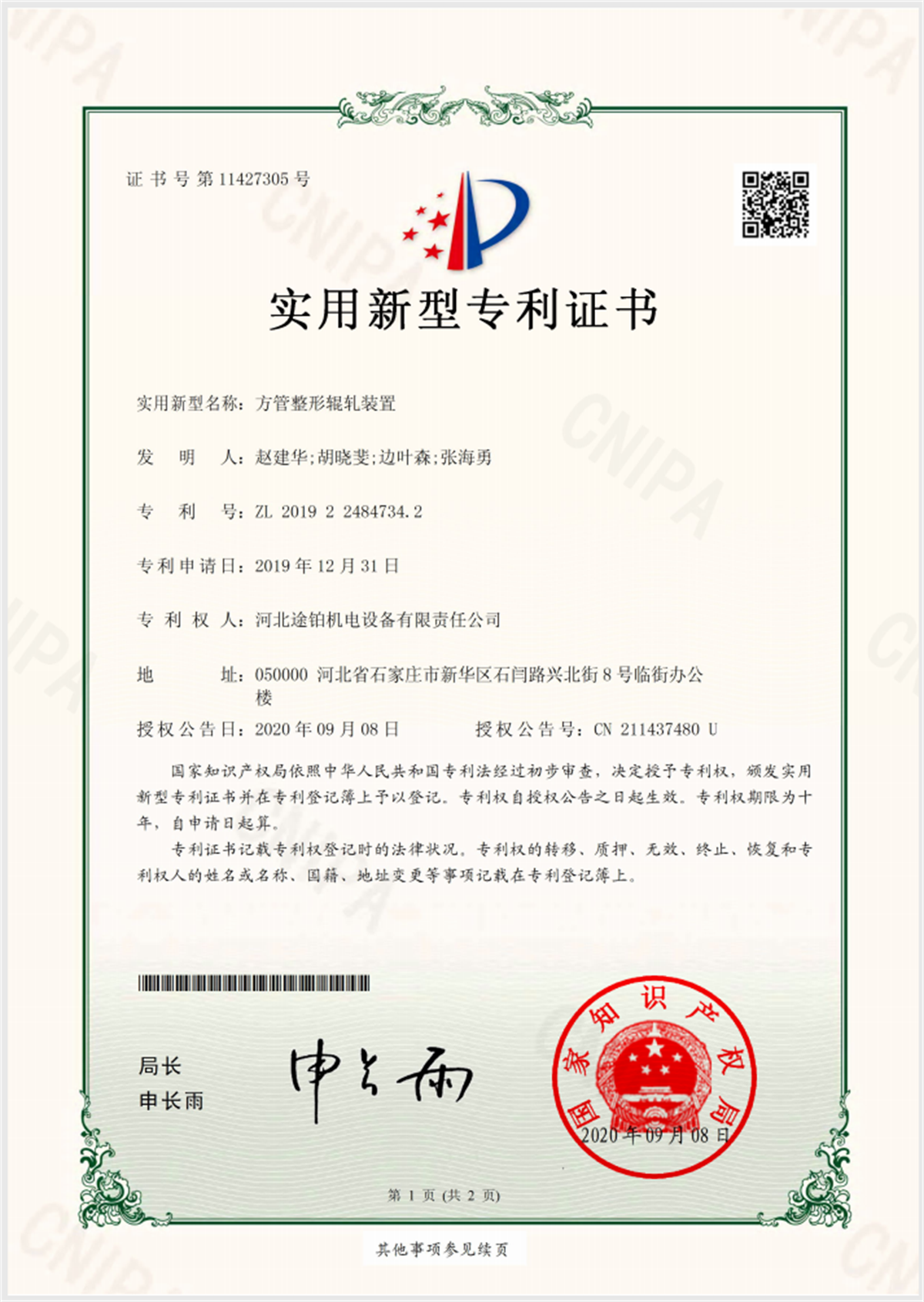

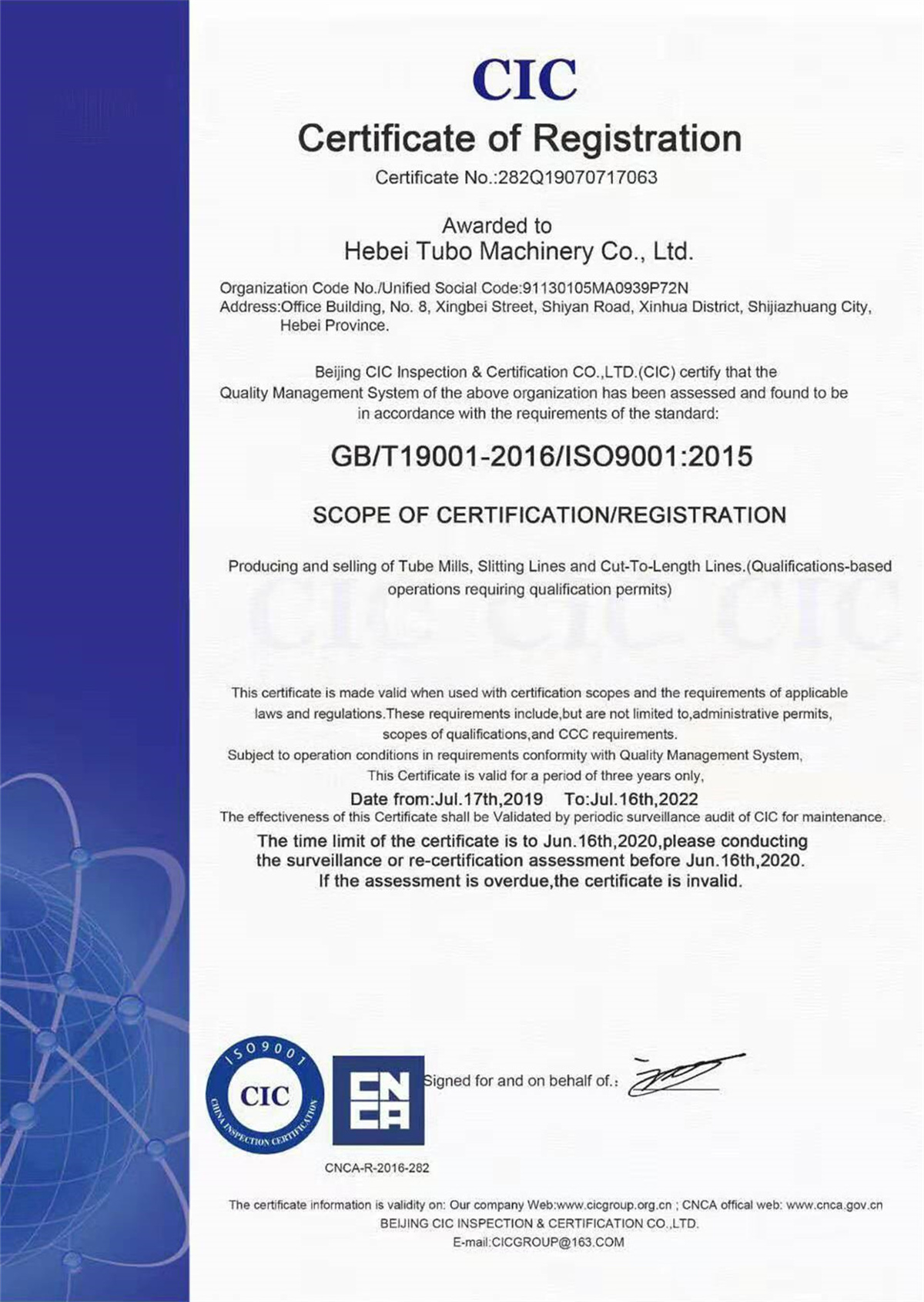

Our Certificate

Field Visits

Our advantage

1)We have our own CNC Machining Center, We can control cost and deliverly time.

2) More than 15 years R&D and Manufacturer Experience.

3) We can customized according to customer’s requirements.

4) We have professional researching, designing, processing, testing and after-sale service teams.

5) We can Strict quality control in raw material, processing accuracy,heat treatment,assembling accuracy,standard components and so on. Strict inspection for equipment before delivery.

Packing&shipping

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.