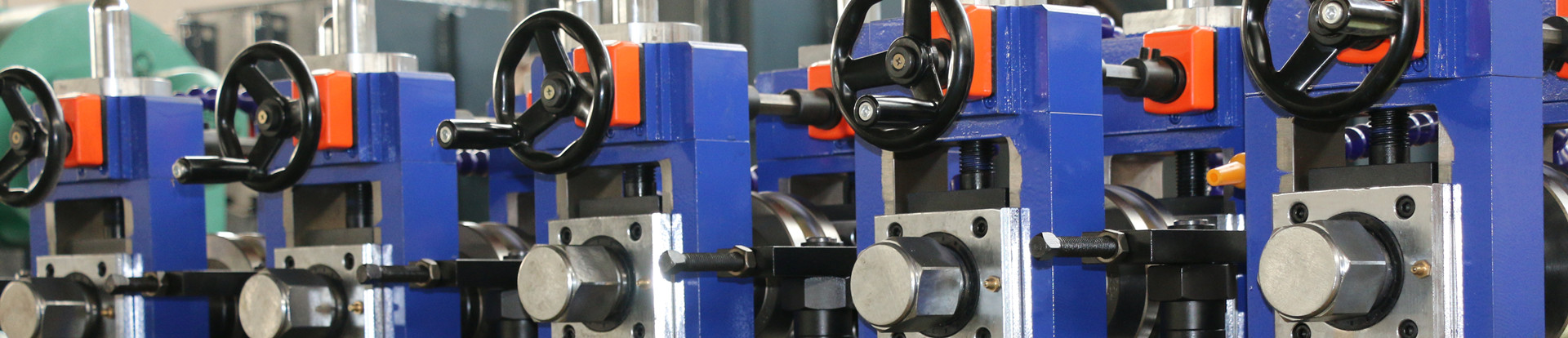

Factory Promotional 12 Steel Pipe Mill - Ferrite Rod – TUBO Detail:

Product Description

The rod is constructed of Ferrite material and is an essential accessory for using in high frequency welding of tubes and pipes.The Mn-Zn ferrite material best meets the demanding requirements of high frequency welding.

Advantage

1.The ferrite rod lowers the reluctance of the magnetic path, thereby saving energy and improving overall process efficiency.

2.High saturation flux combined with high resistance reducing eddy current losses improves mill efficiency.

3.Its high density construction adds the mechanical strength for long life in the severe operating environment in a steel tube mill.

Specification

|

Size(D*L) |

Quality/Box |

Size(D*L) |

Quantity/Box |

Size(D*L) |

Quantity/Box |

|

10×100 |

432 |

10×140 |

216 |

10×200 |

216 |

|

11×100 |

432 |

11×140 |

216 |

11×200 |

216 |

|

12×100 |

360 |

12×140 |

180 |

12×200 |

180 |

|

13×100 |

300 |

13×140 |

150 |

13×200 |

150 |

|

13.5×100 |

300 |

13.5×140 |

150 |

14×200 |

150 |

|

14×100 |

300 |

14×140 |

150 |

15×200 |

150 |

|

15×100 |

300 |

15×140 |

150 |

16×200 |

120 |

|

16×100 |

240 |

16×140 |

120 |

17×200 |

96 |

|

17×100 |

192 |

17×140 |

96 |

18×200 |

96 |

|

18×100 |

192 |

18×140 |

96 |

20×200 |

90 |

|

20×100 |

192 |

20×140 |

96 |

22×200 |

54 |

|

22×100 |

108 |

22×140 |

54 |

24×200 |

54 |

|

25×100 |

108 |

24×140 |

54 |

25×200 |

54 |

|

28×100 |

108 |

25×140 |

54 |

28×200 |

54 |

|

30×100 |

72 |

28×140 |

54 |

30×200 |

36 |

|

32×100 |

72 |

30×140 |

36 |

32×200 |

36 |

|

35×100 |

48 |

32×140 |

36 |

35×200 |

24 |

|

38×100 |

24 |

25×140 |

24 |

36×200 |

24 |

|

36×100 |

24 |

38×140 |

24 |

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary goal. We uphold a consistent level of professionalism, quality, credibility and service for Factory Promotional 12 Steel Pipe Mill - Ferrite Rod – TUBO , The product will supply to all over the world, such as: Vietnam , Serbia , UK , With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we are striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!