Factory supplied 6 Welded Pipe Mill - Shear And Welder – TUBO Detail:

Product Description

Shear&Butt welder is used to shear the irregular ends of steel strip and weld steel strips of two coils together. Thus ensuring the continuous production.

Specification

| Type | Shear Type | Centering Type | Welding Type |

| Manual shear&Manual welding | Manual | Manual | Manual |

| Hydraulic shear&Manual welding | Hydraulic | Manual | Manual |

| Hydraulic shear&Auto welding | Hydraulic | Manual | Automatic |

| Hydraulic shear&welding | Automatic | Automatic | Automatic |

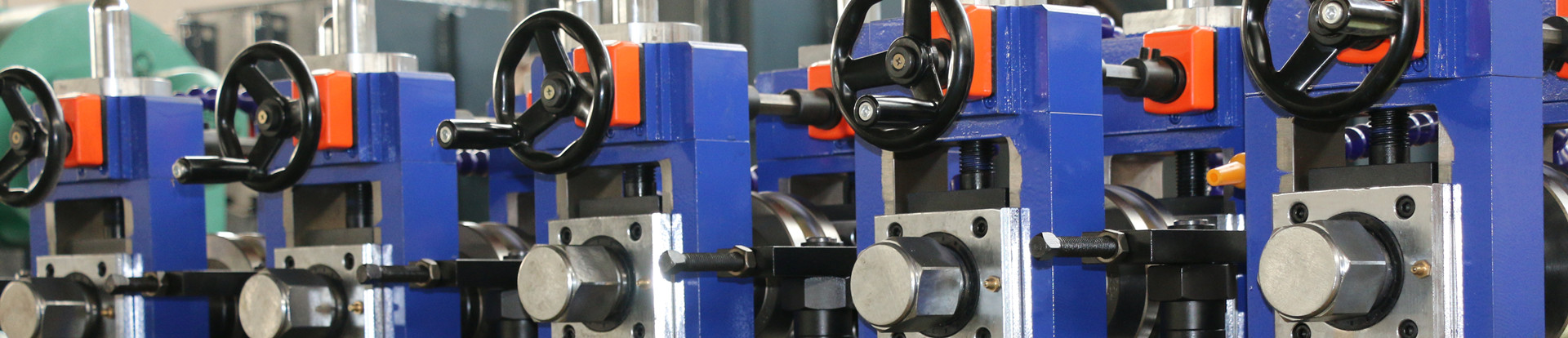

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for Factory supplied 6 Welded Pipe Mill - Shear And Welder – TUBO , The product will supply to all over the world, such as: Spain , Czech , Tanzania , We have now a large share in global market. Our company has strong economic strength and offers excellent sale service. Now we have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.