Factory Supply Orbital Mill Saw - FFX Forming Process – TUBO Detail:

Product Description

FFX is a kind of forming technology developed.

If the customer produces more square or almost all are square pipes, FFX multi-function pipe mill is the best choice.

Advantage

1.Do not need to change moulds in breakdown section ,Saving about 60% cost on the rolls.

2.Roll chaning time is cut down greatly, Save time.

3.Breakdown section does not need to change moulds and just adjust is ok , and it can cut-down producing period.

4.Release Labor intensity.

5. The steel strip is distorted and beared more reasonably, to reduce the rub between the strip and roller, and also reduce the waste of the roller .

6. It is easier to restore and adjust roller .

Specification

|

Model |

Round Pipe |

Square & Rectangular Pipe |

Spee(m/min) |

||

| Dia.(mm) | Thickness(mm) | Dia.(mm) | Thickness(mm) | ||

| ERW32 | 10 - 38mm | 0.5 – 2.0mm | 10×10-30×30mm | 0.5 – 1.6mm | Max.120m |

| ERW50 | 15 – 51mm | 0.5 – 2.5mm | 15×15-40×40mm | 0.5 – 2.0mm | Max.120m |

| ERW60 | 16 – 60.3mm | 0.5 – 3.0mm | 15×15-50×50mm | 0.5 – 2.5mm | Max.120m |

| ERW76 | 20 – 76mm | 1.0 – 4.0mm | 20×20-60×60mm | 1.0 – 3.0mm | Max.120m |

| ERW89 | 25 – 89mm | 1.0 – 4.5mm | 20×20-70×70mm | 1.0 – 3.5mm | Max.120m |

| ERW114 | 38 – 114mm | 1.0 – 5.0mm | 40×40-90×90mm | 1.0 – 4.0mm | Max.80m |

| ERW165 | 60 – 165mm | 2.0 – 6.0mm | 50×50-150×150mm | 2.0 – 5.0mm | Max.60m |

| ERW219 | 89 – 219mm | 3.0 – 8.0mm | 80×80-200×200mm | 3.0 – 8.0mm | Max.50m |

| ERW273 | 114 – 273mm | 4.0 – 10.0mm | 100×100-250×250mm | 4.0 – 10.0mm | Max.40m |

| ERW325 | 165 – 325mm | 4.0 – 12.7mm | 100×100-300×300mm | 4.0 – 12.0mm | Max.30m |

| ERW426 | 219 – 426mm | 5.0 – 14.0mm | 150×150-350×350mm | 5.0 – 14.0mm | Max.30m |

| ERW508 | 219 – 508mm | 6.0 – 16.0mm | 200×200-400×400mm | 6.0 – 16.0mm | Max.25m |

| ERW610 | 325 – 610mm | 6.0 – 18.0mm | 250×250-500×500mm | 6.0 – 18.0mm | Max.25m |

| ERW720 | 355 – 720mm | 6.0 – 20.0mm | 300×300-600×600mm | 6.0 – 20.0mm | Max.25m |

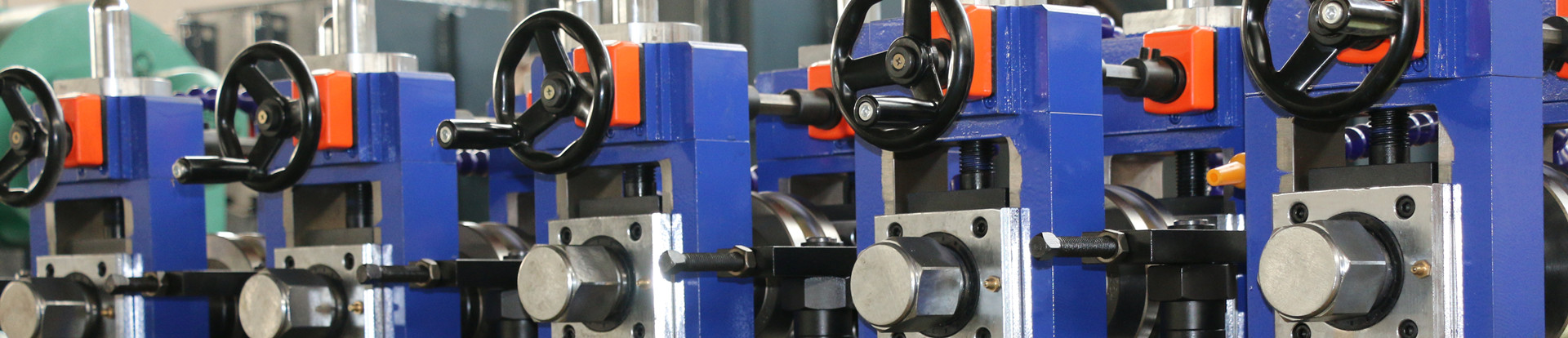

Product detail pictures:

Related Product Guide:

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Factory Supply Orbital Mill Saw - FFX Forming Process – TUBO , The product will supply to all over the world, such as: Panama , Botswana , New Orleans , We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.