High Performance High Frequency Welded Steel Tube Line - Automatic Packing Machine – TUBO Detail:

Steel Tube & Pipe Automatic packing Machine:

Automatic Stacking and Bundling Machine

Automatic packing machine is used to collect, stack steel pipe into 6 or 4 angles, and bundle automatically. It runs stably without manual operation. Meanwhile, eliminate the noise and knocking of shock of steel pipes. Our packing line can improve your pipes quality and production efficiency, reduce cost, as well as eliminate potential safety hazard.

Advantage

1.Stacking and Packing AUTOMATICALLY.

2.Perfect surface tube.

3.Less labors, Lower working strength.

4.Automatic operation, lower noisy.

Working procedure

The pipes are transported to the packing area by the run-out table:

1.Pipes turning to packing machine

The pipes will be turned to the packing machine chain transportation device by the pipe turning device and then moved to the pipe counting position;

2.Pipe counting and stacking

The system has the set program that how many pieces of pipes will needed in a bundle for different sizes,then the system will send order to the machine counting and accumulating the pipes layer by layer until enough pipes are collected;the pipe collecting device will go down the height of one layer when one layer of pipes are collected and pushed to the collecting device;there is also one end alignment device at one end;

3.Bundle transportation

The whole bundle of pipes will be moved to the bundling position by the transporting car,then the collecting device will return to the collecting position waiting for a new bundle;

4.Automatic bundling device

The hanging automatic bundling device will work as the set bundling belt position requirement step by step; the progress are: the bundling machine will move down to the bundling position and contact the top layer of pipes, the belt guiding channel will close, the bundling head will send out the belt, connecting the belt end, then tightening the belt , buckling and then cut the belt; after that the belt guiding channel will open, the bundling head will return to the original position and preparing the next bundling;

The bundled pipes will be transported to the storing position by the storing chain transporting device, the transporting car will return and waiting for the next bundle;

5.Storing

The storing area will store three bundles and will be moved to the finished pipes area by the crane;

Cycling : the whole process will be controlled by the industrial PLC automatically, also has the function of manual and automatic control to guarantee the continuous production and working durability;

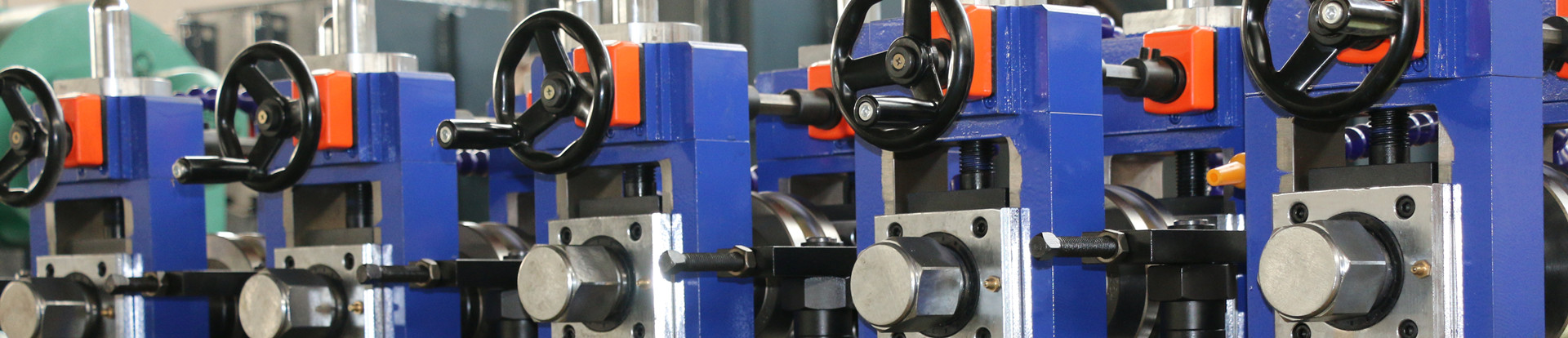

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for High Performance High Frequency Welded Steel Tube Line - Automatic Packing Machine – TUBO , The product will supply to all over the world, such as: Dubai , Japan , Cyprus , We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.