High Performance Tube Straightening Machine - Shear And Welder – TUBO Detail:

Product Description

Shear&Butt welder is used to shear the irregular ends of steel strip and weld steel strips of two coils together. Thus ensuring the continuous production.

Specification

| Type | Shear Type | Centering Type | Welding Type |

| Manual shear&Manual welding | Manual | Manual | Manual |

| Hydraulic shear&Manual welding | Hydraulic | Manual | Manual |

| Hydraulic shear&Auto welding | Hydraulic | Manual | Automatic |

| Hydraulic shear&welding | Automatic | Automatic | Automatic |

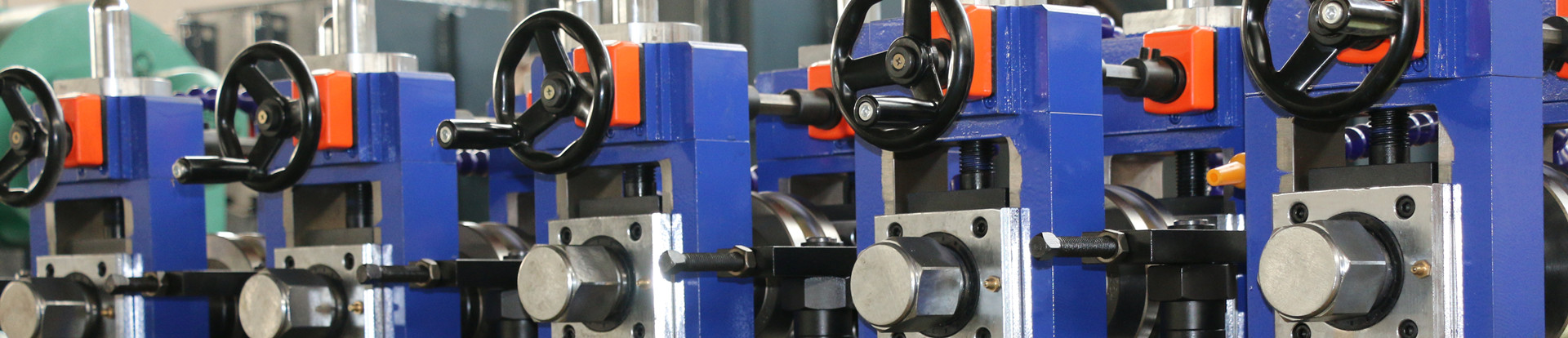

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for High Performance Tube Straightening Machine - Shear And Welder – TUBO , The product will supply to all over the world, such as: Brisbane , Sri Lanka , Armenia , With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.