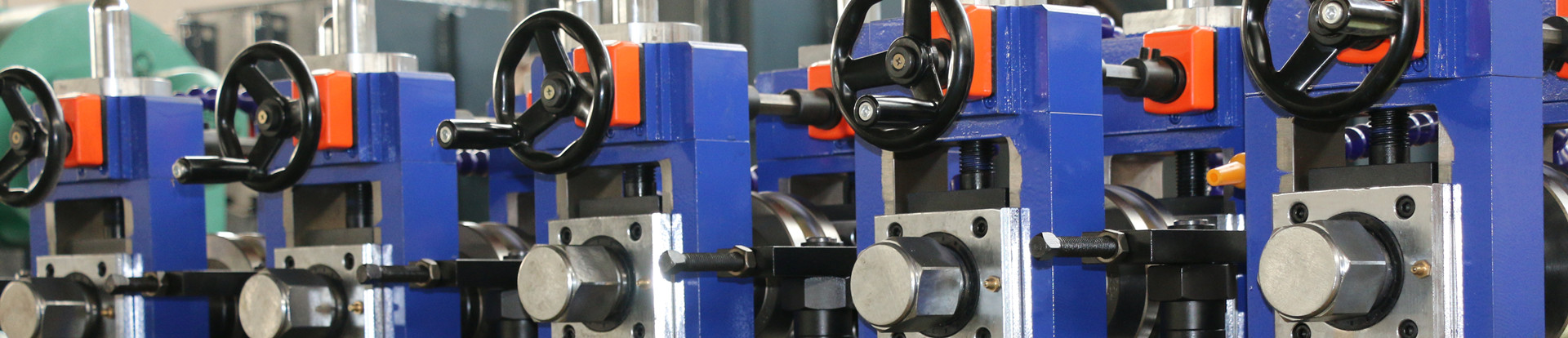

High Quality 114mm Erw Welded Pipe Mill - Rollers – TUBO Detail:

Product Description

Used for roll forming of steel tubes, Specific sets of rollers can be used to bend strip steel into steel tubes of the required Diameter.

Tube Roller Process

In order to obtain qualified modes, we built a quality control system and applied this process:Raw material – sawing material – rough processing – Drilling –fine finishing – roller polishing – Typing Code – semi-finished product inspection – heat treatment – grinding hole – horizontal die cutting – quality inspection – oil cleaning – packaging

Specfication

| Material | GCr15, Cr12,Cr12MoV, Can be customized |

| Hardness of roller | HRC58-62 |

| Deepness of quench hardening | ≥ 10mm |

| Roughness of surface | Ra≤0.8um |

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with High Quality 114mm Erw Welded Pipe Mill - Rollers – TUBO , The product will supply to all over the world, such as: Swaziland , Oman , Madagascar , Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.