Manufacturing Companies for 150kw High Frequency Welder - Pneumatic Combination Of Steel Pneumatic Balers – TUBO Detail:

Product Descripation

GZA-32/25 Pneumatic Combination of steel strapping machine is a complete package of the machine to complete the process of binding, bite buckle, cut with intergrated.

Appliaction: Mainlyl used in steel companies and non-ferrous metal companies bundle a variety of pipe,sheet, profiles, ingots and other products.

Feature

1.A combination of steel balers, pneumatic tightening, bite buckle, cut with integrated integration.

2.Pneumatic operation, Tightening efforts.

3.Using advanced technology,stable performance.

4.Combined balers can use 19,32mm width of the strip (optional one )

Specification

| Product Name | Gza-32/25 combined pneumatic steel strapping machine |

| Product series | KZ Pneumatic strapping machine series |

| Product Type | GZA-32/25 |

| Tying material | Steel |

| Use of steel width | 19mm,32mm,(optinal one) |

| Use strip thickness | 0.8~1.2mm |

| Steel tensioning speed | 5.3m/min |

| Tension | ≥9.8kn/0.6Mpa |

| Locking part of the tensile strength | ≥18.4KN |

| Machine weight | 15kg |

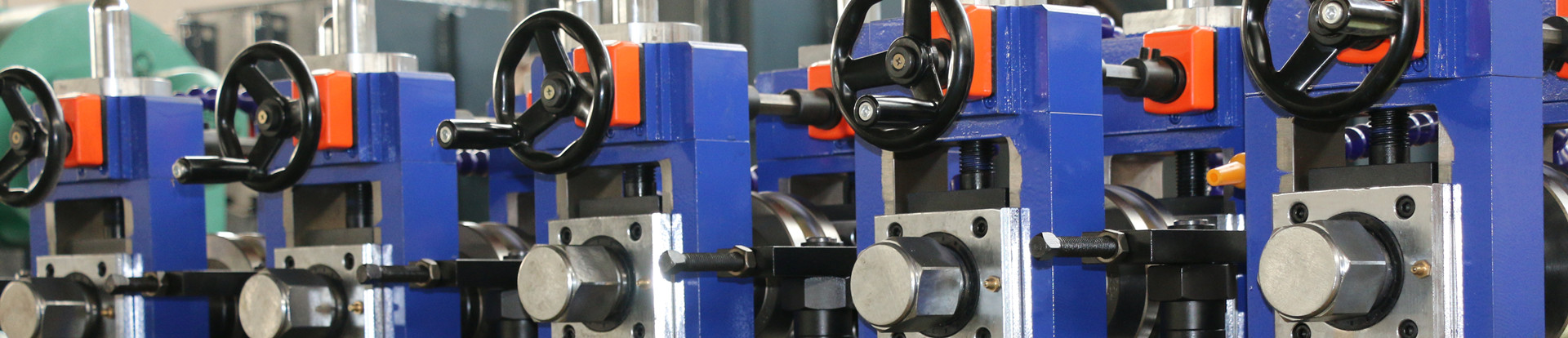

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of Manufacturing Companies for 150kw High Frequency Welder - Pneumatic Combination Of Steel Pneumatic Balers – TUBO , The product will supply to all over the world, such as: Sweden , Jeddah , United States , We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We are willing to build long-term, friendly and mutually beneficial cooperation with you.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.