OEM Manufacturer Steel Coil Slitting Line 1800mm - H.F Solid Sate Welder – TUBO Detail:

Product Description

Solid state high frequency tube welder for carbon steel, aluminum copper,Stainless steel tube/pipe welding.The whole set of solid state H.F.welder is composed of switch rectifying cabinet,inverter output cabinet, 2-D adjustable bracket,circulation soft water cooling system and central operation cabinet.

Advantage

1.Pollution-free,Low noise,no waste water and no waste gas. Circulating water is used in production to cool down, save energy, protectenvironment and save labor.

2.Suitable for all walks of life such as agriculture and industrialb production.

3.welded pipe equipment have good quality, good welding seam condition,less burr, fast speed,saving energy and cost .

4.Good welding quality, fast welding speed and low power consumption, it has been widely applied and imple-mented.

5.Save a lot of metal processing time and parts.

Specification

| Welding power(KW) | Pipe OD(mm) | Thickness(mm) | Working Speed(m/min) |

| 100 | 10~50 | 0.3~2.0 | ≤120 |

| 200 | 32~76 | 1.0~3.0 | ≤120 |

| 250 | 32~76 | 1.0~4.0 | ≤120 |

| 300 | 45~114 | 1.5~4.5 | ≤90 |

| 400 | 45~165 | 1.5~4.5 | ≤80 |

| 500 | 76~219 | 2.0~6.5 | ≤80 |

| 600 | 76~273 | 3.0~9.0 | ≤60 |

| 800 | 89~325 | 4.0~12.7 | ≤50 |

| 1000 | 165~610 | 6.0~19.0 | ≤30 |

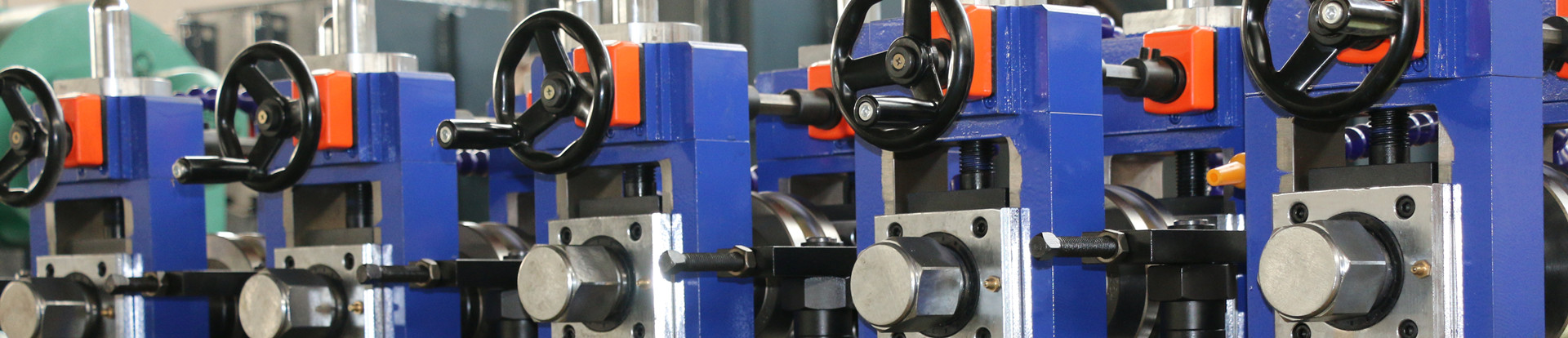

Product detail pictures:

Related Product Guide:

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for OEM Manufacturer Steel Coil Slitting Line 1800mm - H.F Solid Sate Welder – TUBO , The product will supply to all over the world, such as: Islamabad , Algeria , Kuwait , All the employees in factory, store, and office are struggling for one common goal to provide better quality and service. Real business is to get win-win situation. We would like to provide more support for customers. Welcome all nice buyers to communicate details of our products with us!

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!