OEM manufacturer Steel Sheet Cut Machine 1000mm - Uncoiler – TUBO Detail:

Product Description

Un-Coiler is the important equipment of entrance section of pipe mill line. Mainly used to hold steel strip to make coils unfold. Supplying raw material for the production line .

Classification

1.Double Mandrels Uncoiler

Two mandrels to prepare two coils, automatic rotating, expanding/shrinking/braking using a pneumatic controlled device, with press roller and side arm to prevent coil loosening and turning over.

2.Single Mandrel Uncoiler

Single Mandrel to load heavier coils, hydraulic expanding/shrinking, with press roller to prevent coil loosening, comes with a coil car to help coil loading.

3.Double Cone Uncoiler by hydraulic

For heavy coils with a large width and diameter, double cones, with coil car, automatic coil up-loading and centering.

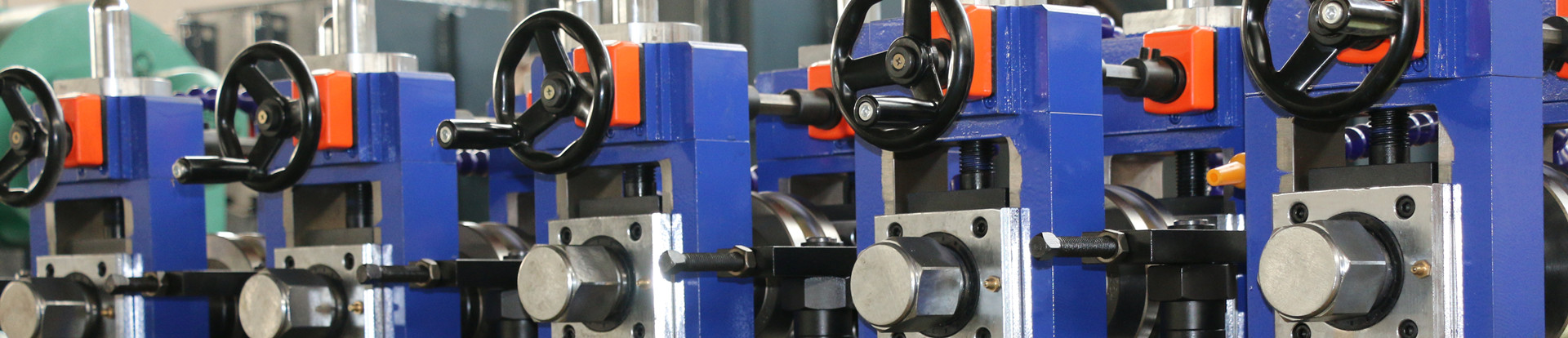

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with OEM manufacturer Steel Sheet Cut Machine 1000mm - Uncoiler – TUBO , The product will supply to all over the world, such as: San Francisco , Paraguay , Sacramento , We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.