Quality Inspection for Induction Welding Machine - Flattener – TUBO Detail:

Product Description

Flattener is used to flat the ends of steel strip after uncoiler, includes the pinching roll and flattening roll, Providing the convenience for the next processing shear&Butt welding device.

Specification

| Type | Width(mm) | Thickness(mm) | Speed(m/min) | Structure |

| Φ50 | 40~200 | 0.8~3.0 | 12 | 5 rollers |

| Φ76 | 100~260 | 0.8~3.5 | 12 | 5 rollers |

| Φ127 | 120~400 | 1.0~4.0 | 8 | 5 rollers |

| Φ140 | 160~440 | 1.0~4.5 | 6 | 7rollers |

| Φ165 | 280~520 | 2.0~6.0 | 6 | 7rollers |

| Φ219 | 360~700 | 2.0~8.0 | 6 | 7rollers |

| Φ273 | 520~860 | 4.0~10.0 | 6 | 7rollers |

| Φ325 | 500~1020 | 4.0~12.0 | 6 | 7rollers |

| Φ426 | 600~1300 | 6.0~16.0 | 6 | 7rollers |

| Φ508 | 700~1650 | 6.0~18.0 | 6 | 7rollers |

| Φ630 | 900~2000 | 6.0~22.0 | 6 | 7rollers |

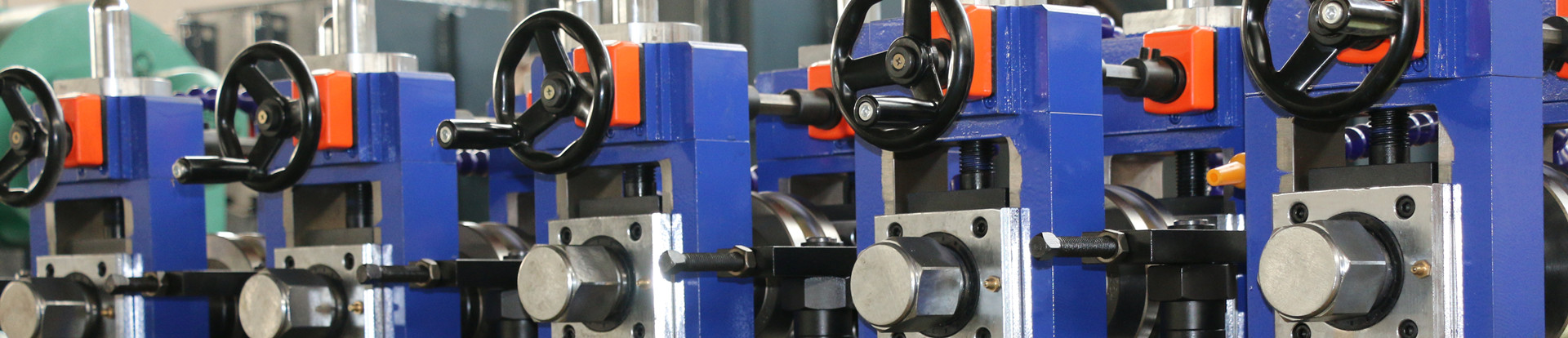

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for Quality Inspection for Induction Welding Machine - Flattener – TUBO , The product will supply to all over the world, such as: Jakarta , Mexico , Provence , We aim to become the modern enterprise with the commercial ideal of "Sincerity and confidence" and with the aim of "Offering customers the most sincere services and best quality products". We sincerely ask for your unchanged support and appreciate your kind advice and guidance.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!