Super Purchasing for Tube Welding Machine - Uncoiler – TUBO Detail:

Product Description

Un-Coiler is the important equipment of entrance section of pipe mill line. Mainly used to hold steel strip to make coils unfold. Supplying raw material for the production line .

Classification

1.Double Mandrels Uncoiler

Two mandrels to prepare two coils, automatic rotating, expanding/shrinking/braking using a pneumatic controlled device, with press roller and side arm to prevent coil loosening and turning over.

2.Single Mandrel Uncoiler

Single Mandrel to load heavier coils, hydraulic expanding/shrinking, with press roller to prevent coil loosening, comes with a coil car to help coil loading.

3.Double Cone Uncoiler by hydraulic

For heavy coils with a large width and diameter, double cones, with coil car, automatic coil up-loading and centering.

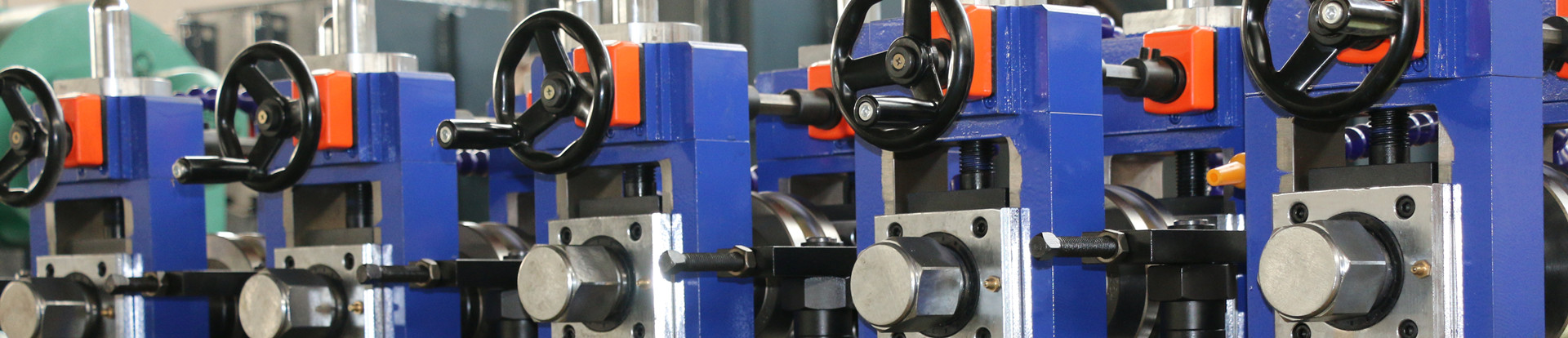

Product detail pictures:

Related Product Guide:

We are convinced that with joint efforts, the business between us will bring us mutual benefits. We can assure you product quality and competitive price for Super Purchasing for Tube Welding Machine - Uncoiler – TUBO , The product will supply to all over the world, such as: Rwanda , Sierra Leone , Monaco , We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!